Do-It-Yourself Washout Booth for Screen Printing

I’ve seen several tutorials on building a screen printing washout booth online using an old shower and building a wooden structure around it. This is fairly inexpensive if you’re able to find an old shower stall. I looked all over my local area and could not get my hands on one so I thought of using a 55 gallon plastic barrel, setting it on its side, cutting a hole to allow a screen to fit inside of it. However I was soon realizing that the size wasn’t going to be quite big enough so I went with option #2.

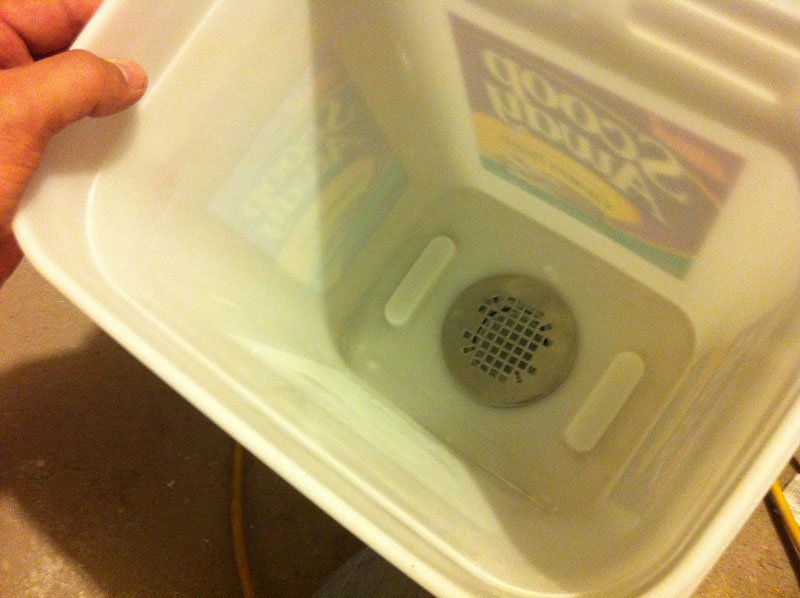

I also added a 90° 2″ pvc elbow and a threaded adapter which fit perfectly onto the ball-valve drain. With the base made entirely of bars, attaching the filter only needed a budgie cord. I did have to cut out the horizontal bar from the support cage to allow for the drain to fit through.